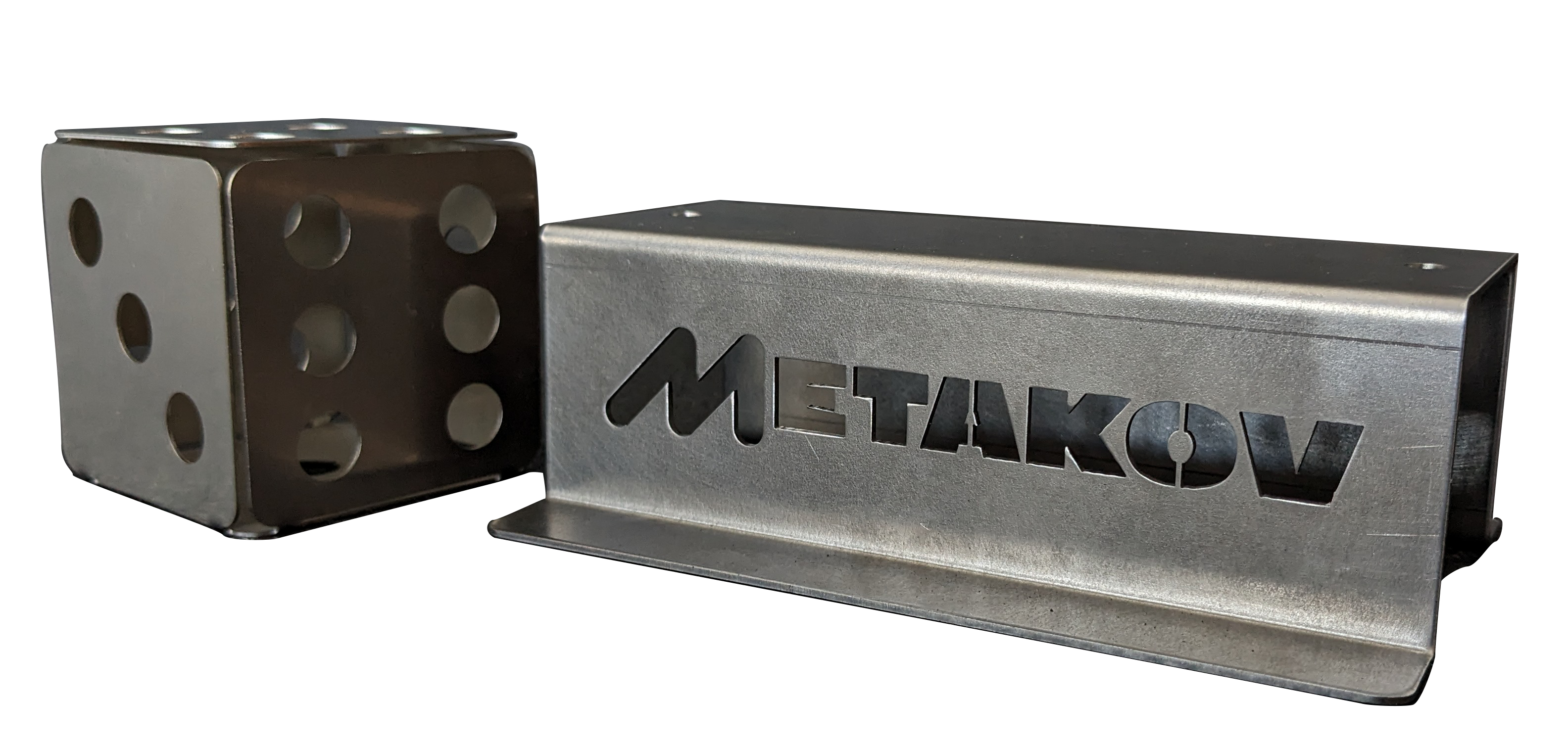

Sheet metal bending

CNC press brakes forming

At METAKOV, we specialize in sheet metal bending using servo-hydraulic and servo-electric bending technologies. Our entire bending process is optimized to ensure precision and offer bending of complex parts and intricate shapes.

With nearly 20 years of experience, we have expertise in bending sheet metal frames, panels, containers, brackets, and similar components. We typically work with structural and stainless steel, aluminum, and its alloys. Ensuring the elimination of tooling marks is standard practice for us.

Our technologies

Machines using servo-hydraulic

and servo-electric bending technologies

Bending and forming various types of sheet metal are carried out based on individual customer requirements. In our manufacturing process, we utilize dynamic CNC bending presses, ensuring high precision even under high workload. With a pressing force of up to 175kN, we standardly bend sheets up to 12mm thick and can bend components from steel products or sheets up to a length of 3000mm.

Whether you need to bend a large series or a single piece for prototyping, ensuring high repeatability and precision according to STN EN ISO 2768-cL is our norm.

We achieve excellent operational performance in any metal bending operation, from small parts with single bends to larger complex parts with multiple bends and lengths.

Accompanying technologies

Frequently Asked Questions