SHEET METAL PUNCHING

STAMPING OF METAL SHEETS

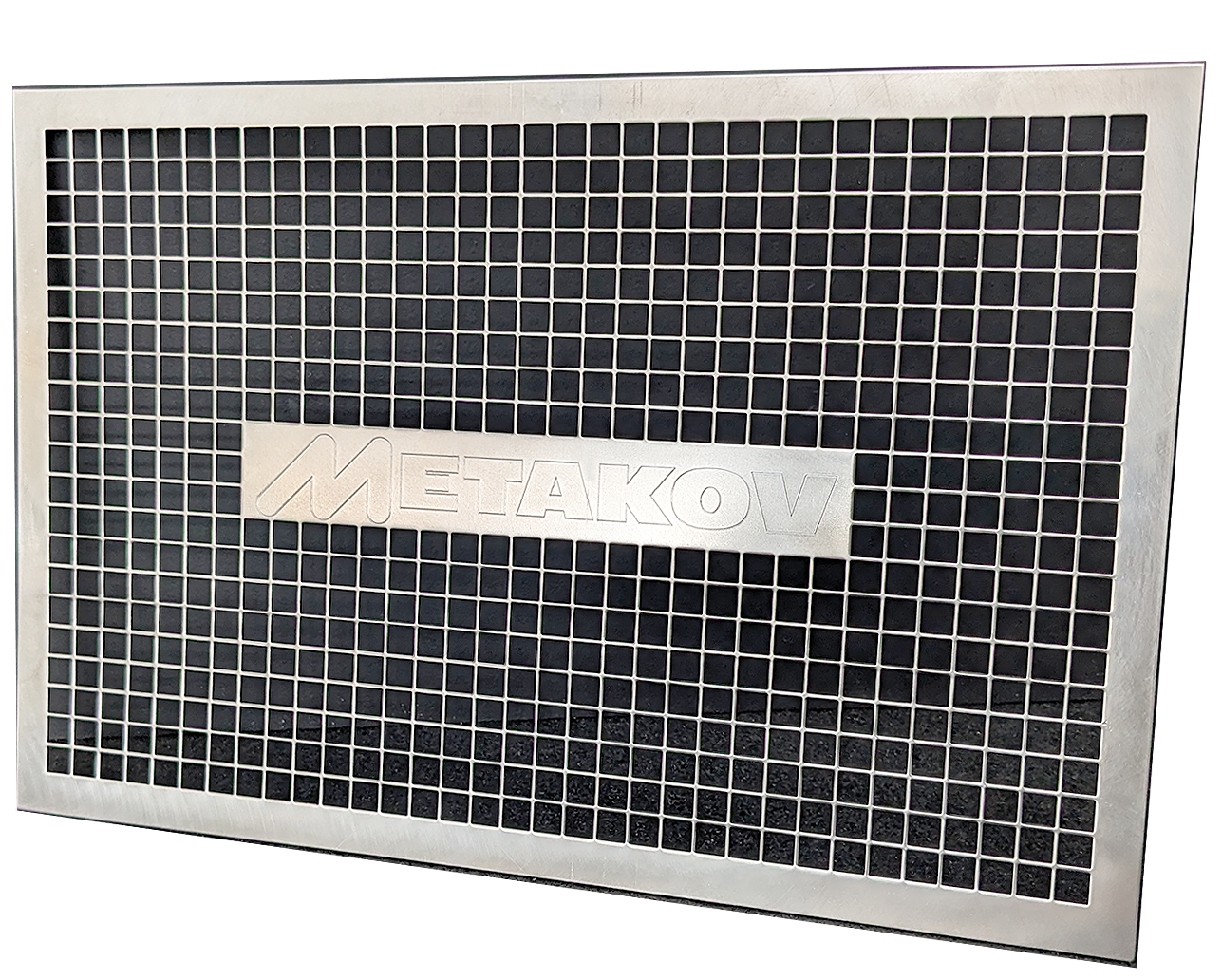

Sheet metal punching is a highly progressive, innovative, and efficient technology that enables the cutting and forming of sheet metal with high productivity and precision at relatively low costs. It is particularly suited for sheet metal parts up to 4 mm thick and is ideal for high-volume production. This technology is fully automated, ensuring consistent accuracy of the finished parts. Additionally, the manufacturing process is designed to prevent unnecessary scratching of the material.

Our technologies

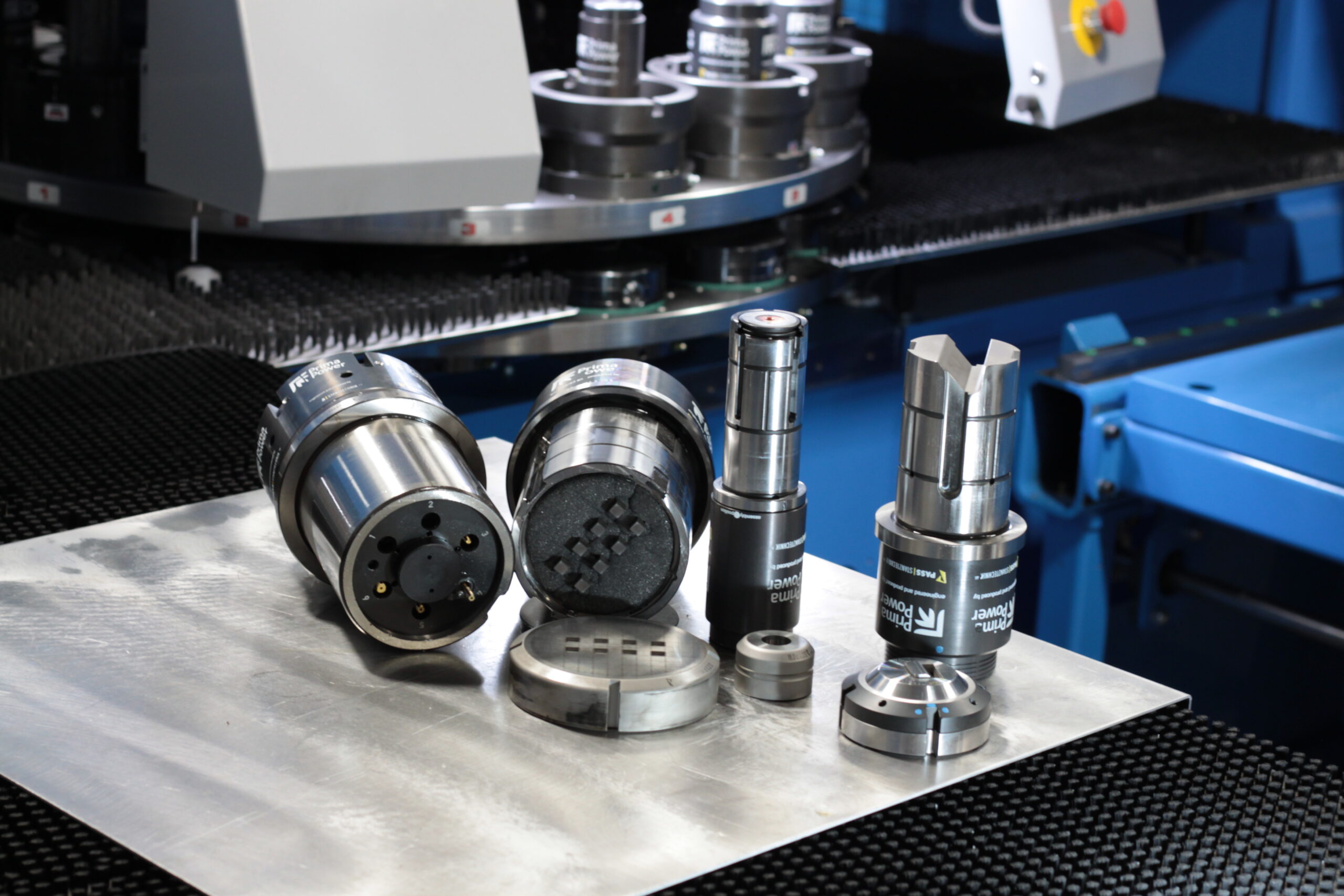

CNC servoelectric punching machine combined with laser cutting

The latest highly efficient technology combines punching and cutting, designed for the production of a wide range of sheet metal parts. The automated manufacturing process uses a turret head to perform punching, nibbling, cutting, forming, bending, and threading in a single step, achieving high repeatability and production efficiency.

A punching press with a press force of 250 kN can punch circular and special holes with high repeatability up to a standard dimension of 88.9 mm, form parts with upforming capabilities (forming upwards) up to dimensions of 80 x 25 mm, create formed threads up to M8 standard with the option of adding a collar to optimize thread strength in thin sheets, and perform many other technological operations, such as marking sheet metal parts with special tools for labeling and engraving. All operations are performed on a brush table, minimizing the risk of surface scratches.

Accompanying technologies

Frequently Asked Questions